End seminar for CHANGE and Wasted Textiles

In order to set a final punctuation for two major research projects that have run parallel over the last five years, Consumption Research Norway Clothing division invited partners and interested parties to an closing hybrid seminar.

The title ‘More and more and more’ – when both projects have been about lessening the environmental burden and deplastification of textiles – must have intrigued many, as 76 people participated online and the physical attendance at OsloMet saw a healthy turn-out.

The seminar was divided into three parts: Context, New Knowledge and Offspring. Ingun Klepp set the scene in the first part, describing the context and unanticipated developments during the projects’ five-year period: the pandemic and the launch of EU’s Textile strategy. These two events impacted how the projects needed to reorient themselves relating to some of the work.

The main part was the presentation of new knowledge from the partners, which was led with warm humor by Kate Fletcher (Manchester Metropolitan University) and Jens Maage (SIRK Norge). Short snapshots from both projects were disseminated with graphs, key take-aways and publications. Relating to key take-aways, Bjørn Sverre Hol Haugen from the Norwegian Folk Museum did a stellar job of presenting how the interaction between research and historic knowledge gave grounds for new knowledge, using museum artifacts and wardrobes to better understand how the use of apparel has changed relating to variety – and also to sustainable consumption patterns and discourse.

Other highlighted learnings were results presented by Kirsi Laitala on how there is a lack of correlation between more repair and reuse and less buying of new stuff, an assumption often misused in EU’s policy work. And that we must look much more at the constant and aggressive marketing that is bombarding consumers, ie the bigger picture of what pressures we are being exposed to. This also surfaced in Vilde Haugrønning’s PhD work with couples’ wardrobes, where it is clear that women do have much larger wardrobes than men, and men find it easier to actually find what they are looking for in the market to serve their clothing needs. More research on what societal pressures and expectations are underlying these dynamics begs exploring. Anna Schytte Sigaard’s PhD work – which is on the disposal drivers – also brought forward the societal acceptable mechanisms that encourage the flow-through of ever-increasing apparel. That 10 percent of what is discarded is as good as new, and only 20 percent is deemed as ‘used up’, shows the uselessness of the EU Textile strategy’s focus on more durable and repairable goods. The triangle of consumption, capitalism and care will be interesting to read more about!

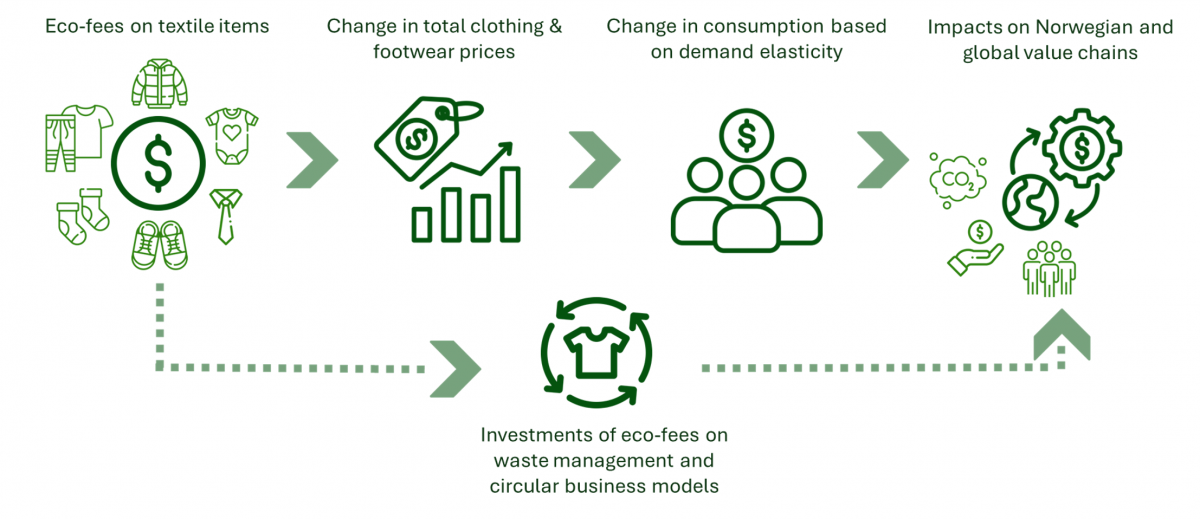

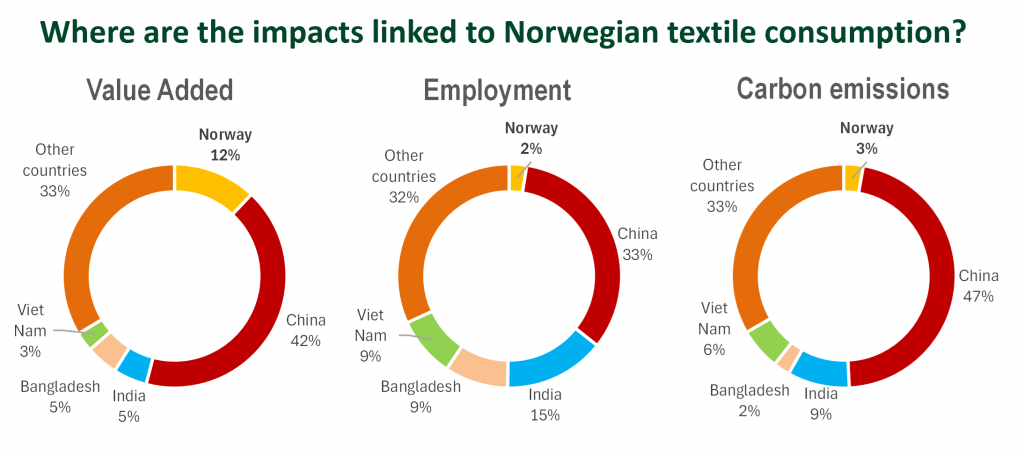

We also learned through SINTEF’s Meron Assefa Arega’s presentation that the size of an EPR fee will decide how effective it is, which is in line with Ingun’s Targeted Producer Responsibility idea that we have been trying to sell to the EU as a much better idea than the current EPR set-up. Gisle Mardal from NF&TA did his best to deflect any radical ideas on how the sector could be curbed or capped, while Irene Maldini showcased how the EU doesn’t want to hear anything relating to degrowing the massive overproduction – so much in line with the industry’s wishes to keep on doing what they are doing. Irene’s presentation also showcased the desk-top research that has unearthed how the assumption that durability is going to save us and limit overproduction, has no solid foundation in research.

Kerli Kant Hvass spoke about the upcoming EPR legislation, our engagement with TPR (as mentioned above) and the market experiences from ‘circular business models’ like reuse, repair and recycling – and how they struggle in a capitalist, growth-driven economy.

In the last part of the program, Ingun presented examples of budding projects, both some that are operational and others that will hopefully come to fruition. To wrap it all up, both Kate and Ingun spoke about the newest ‘win’, the project Green Blood which will start off in 2026. More to follow shortly!

Back to the title of the seminar ‘More and more and more’ which is borrowed from a book title, and was used since all the tools and measures so far suggested or implemented are drivers for more, not for less. And if we are to actually reduce the environmental burden on the planetary boundaries, we need less of everything – not more. In Jean-Baptiste Fressoz’ book, he describes how energy innovation has not led to energy transitions, but rather the use of more and more and more energy. Very much the same dynamic we see in the textile and fashion sector.

Watch the seminar recording below.