Clothing Research scores at SCORAI 2025

The 2025 SCORAI Europe Conference took place at Lund University in Sweden on April 8-10. SCORAI (Sustainable Consumption Research and Action Initiative) is an international network of researchers and practitioners focused on sustainable consumption. This year’s theme, Mainstreaming Sustainable Consumption, brought together a community of thinkers and doers – including several researchers from SIFO.

By Anna Schytte Sigaard

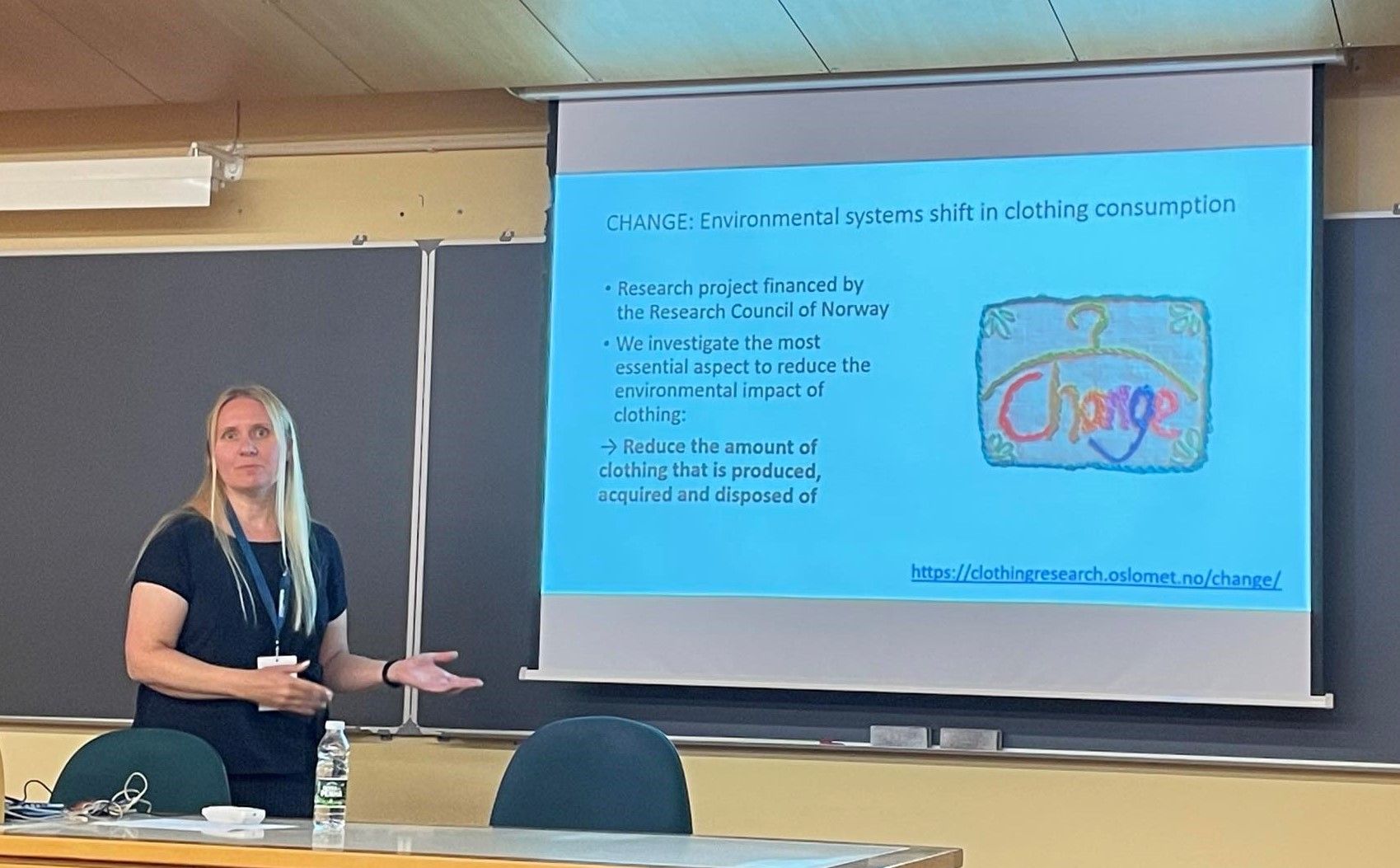

Kirsi Laitala presented a paper from the CHANGE project, co-authored with Irene Maldini, titled “Access to Clothing in a Context of Material Abundance: The Role of Income.” The presentation was part of the session on “Consumption Corridors: Guaranteeing Human Wellbeing Through Upper and Lower Limits to Consumption.” Based on consumer surveys conducted in Norway, Germany, Japan, the UK, and the USA, the study highlighted the need to reduce clothing consumption in affluent societies to achieve social justice and environmental sustainability, noting that clothing consumption continues to grow despite its significant environmental impact

By examining the relationship between household income and clothing consumption, the research reveals that income does not significantly affect the total number of clothing acquisitions, likely due to decreases in the relative price of clothing and access to second-hand clothing. However, higher income does correlate with increased expenditure, purchases of new clothing, and product prices. The findings suggest that future policies aimed at reducing consumption volume in affluent nations should be combined with others that preserve equitable consumption levels in different income groups, involving stakeholders such as clothing companies, resellers, and municipalities.

PhD Research Contributions

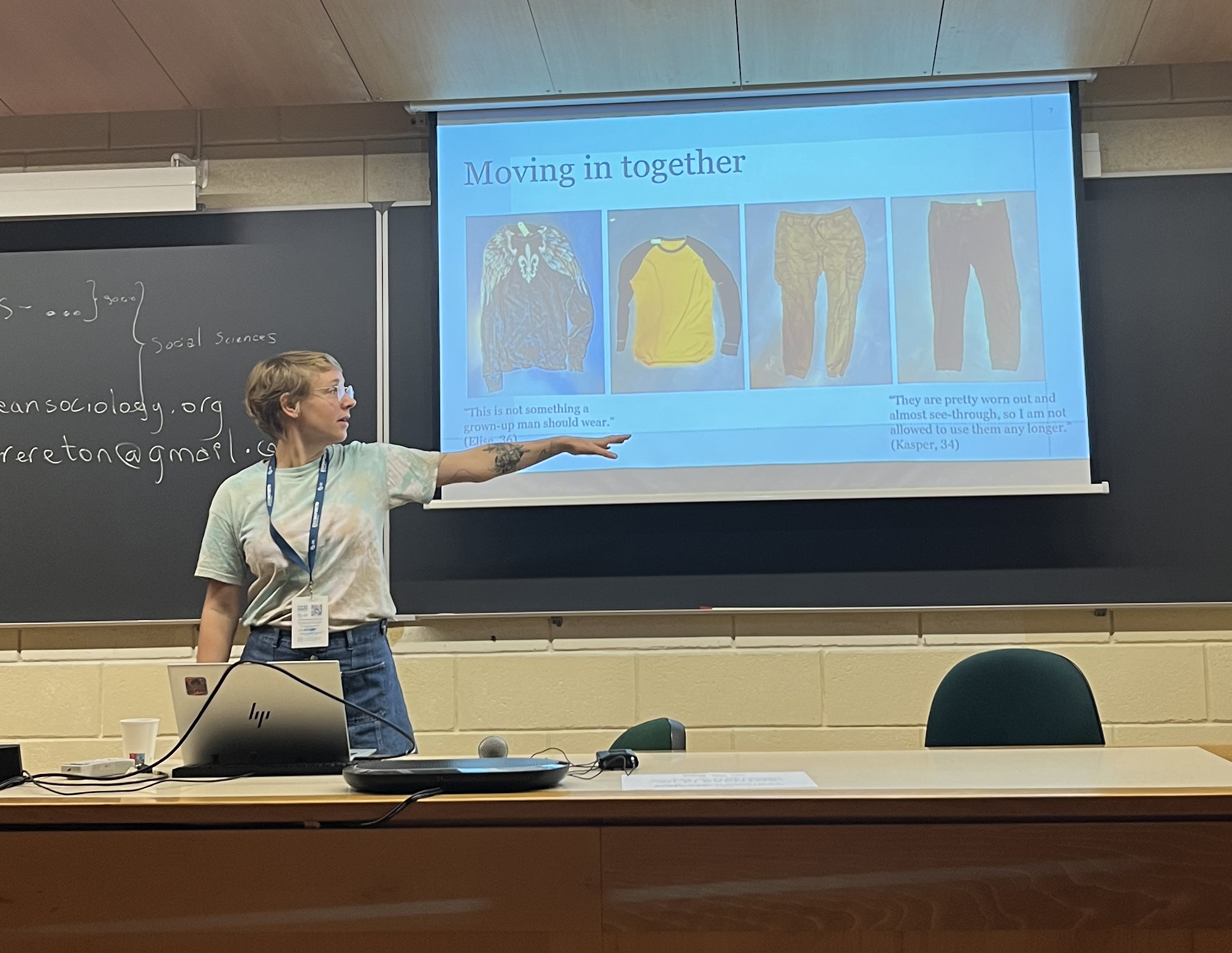

SIFO researchers Vilde Haugrønning and Anna Schytte Sigaard also took stage in the “Practice Theory & Sociology” session. Vilde presented her work titled “The feminization of clothing consumption: Exploring drivers behind garment accumulation from a practice-oriented perspective”. Drawing on fieldwork with 15 Norwegian couples, her research allowed for a gendered comparison between couples that take part in many of the same practices and share the everyday life. Findings showed that acquisition is driven by everyday occasions, emphasizing the habitual nature of clothing consumption. In addition, women’s wardrobes were typically larger and growing faster, particularly among younger participants. While many participants, especially women, expressed a desire to reduce their clothing consumption, structural barriers made this difficult. The findings highlight that clothing acquisition is not simply a matter of personal choice or need, but rather a complex process influenced by gendered expectations around appearance, dress, and social practices.

Anna’s presentation, “Cultural Conventions and the Contradictions of Sustainable Clothing Consumption”, shared early findings from in-depth interviews with 28 Norwegian households about textile disposal. Combining theories of social practice with convention theory, the analysis identified a variety of underlying justification people draw on, ranging from market to civic to environmental reasoning. Interestingly, while many participants referenced sustainability, these justifications often clashed with other cultural norms that still promote acquisition and disposal. The study highlights the tension consumers face when navigating the ideals and realities of sustainable consumption.

SIFO researchers Kirsi Laitala, Harald Throne-Holst, and Ingrid Haugsrud were co-authors in two presentations from the Horizon Europe project CARE. Harald presented “Sustainable Interventions in Clothing Consumption and Food Waste: A Systematic Literature Review,” which was part of the “Interventions Toward Circular Consumption” session. Nina Mesiranta from Tampere University presented “Circular Consumption Behaviour Change from a Practice Theoretical Lens: A Systematic Literature Review,” in the session on “Practice Theory & Sociology.” Both presentations were based on a systematic literature review conducted in the CARE project.

The reviews focused on interventions and their effectiveness in shifting consumer behavior toward more circular and sustainable practices, particularly in food waste and clothing consumption. From a theoretical standpoint, our research aimed to assess the extent to which interventions with practice theory or practice theory-based elements have been applied. We found that the most effective interventions combined multiple strategies or adopted a systems approach. The results of these studies are crucial for guiding future efforts to shift consumer behavior and practices toward greater sustainability, as they highlight effective intervention strategies and provide valuable empirical evidence to inform policy development, helping to design more impactful programs and initiatives.

SIFO also presented two posters:

- “The Impact of Shopping Practices on Reusable Bag Consumption: A Nationally Representative Study from Norway” by Hanna Seglem Tangen and Live Bøyum, and

- “Invasive Products – The Case of Disposable Gloves in Norwegian Everyday Life” by Atle Wehn Hegnes, Kirsi Laitala, and Nina Heidenstrøm.

Both poster presentations aimed to reduce plastics consumption by examining single products such as plastic bags and disposable gloves, to better understand the conditions of their use practices.

Other Conference Contributions on Clothing and Textiles

Two dedicated sessions focused on clothing and textile research.

“Sufficiency business models: Fashion sector case studies” highlighted production-side strategies for a more sustainable fashion industry. Topic included reuse and recycling, marketing approaches to reduced consumption, circular strategies among designers, circular fashion business models, and the “Wellbeing Wardrobe” as a tool for just transitions in the industry.

“Fashion and Textiles”, chaired by Lars Fogh Mortensen (European Environmental Agency), opened with findings from the EEA’s latest report “Circularity of the EU textiles value chain in numbers[1]”.

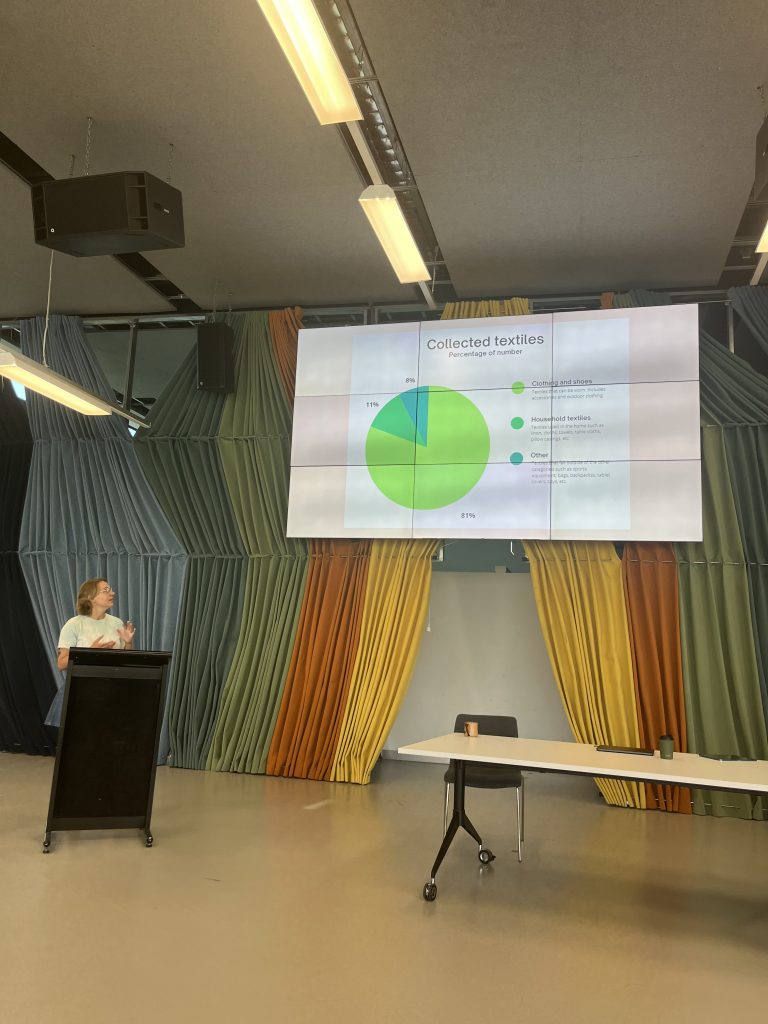

- Arjan de Koning (Leiden University) presented findings based on an examination of the post-consumer textile management chain in the Netherlands including a mapping of stakeholders. They found that tension existed between actors in this network when interests became competing. In addition, they discussed the problems with the legal definition of textile waste as “intention to dispose” as this creates heterogenous perspectives on what waste is and is not.

- Frida Eggert (Lund University) presented findings from her PhD project about secondhand shopping on digital platforms. She has explored the Swedish platform Sellpy enables different modes of shopping. Findings showed that the platform made slow and fast shopping, two opposed models of secondhand clothes shopping, possible at the same time.

- Nicole Berggren (Lund University) explored the repair intention-behavior gap through a case study of Nudie Jeans.

- Mariko Takedomi Karlsson (Lund University) initiated her presentation with a reference to the SIFO publication “The Plastic Elephant”[2]. They carried out a policy document analysis on plastic and textiles investigating the coherence across and between relevant European Commission’s strategies anchored in the Circular Economy Action Plan (CEAP) as well as subsidiary instruments such as directives and regulations. Tentative results indicated a limited coherence between the plastic and textile strategies regarding problem definition and scope, e.g. plastics are mainly discussed in the textiles strategy in relation to microplastic pollution, but not in relation to how integrated plastics and textiles truly are regarding issues of (eco)toxicological risks, fossil fuel use, and climate impacts of production. In addition, the textile strategy differed from other strategies which largely focused on protecting the consumer (for example from hazardous chemicals) whereas the textile strategy focused on consumer responsibility.

- Jason Graham-Nye (University of Technology Sydney) presented their project on sustainable nappy alternatives. They carried out a qualitative field trial of compostable nappies with a collection system in Sydney and presented findings related to the complexities of implementing this sustainable alternative. Among other things, they found that the busy everyday life of parents allowed little room for adoption of new practices. However, their efforts had eventually been successful in Samoa where different systems of waste management had allowed for implementation.

[1] https://www.eea.europa.eu/en/analysis/publications/circularity-of-the-eu-textiles-value-chain-in-numbers

[2] https://oda.oslomet.no/oda-xmlui/handle/11250/3086387