The plastic elephant in the room: Who dares to talk about it?

In the Consumption Research Norway SIFO report The plastic elephant: Overproduction and synthetic fibers in sustainable textile strategies we examine national, international and corporate strategies for sustainable textiles to understand whether, and if so, how they include the problem of increased production volumes based on synthetic materials that can be referred to as the ‘plastic elephant in the room’.

”It’s time to talk about the elephant in the room.” This is a quote from the 2014 GFA Fashion Summit in Copenhagen, when Livia Firth, founder of the consultancy EcoAge and the Green Carpet Challenge, was on a panel with H&M. She challenged the growth issue where “fast fashion brands justify growth by saying that it is the consumers who demand the wide selection and diversity of fashion styles today”. Firth responded to this claim made by H&M’s Helena Helmersson by saying that her children want candy all the time but that does not mean they should have it, and that as a parent she has “a responsibility in addressing this want”.

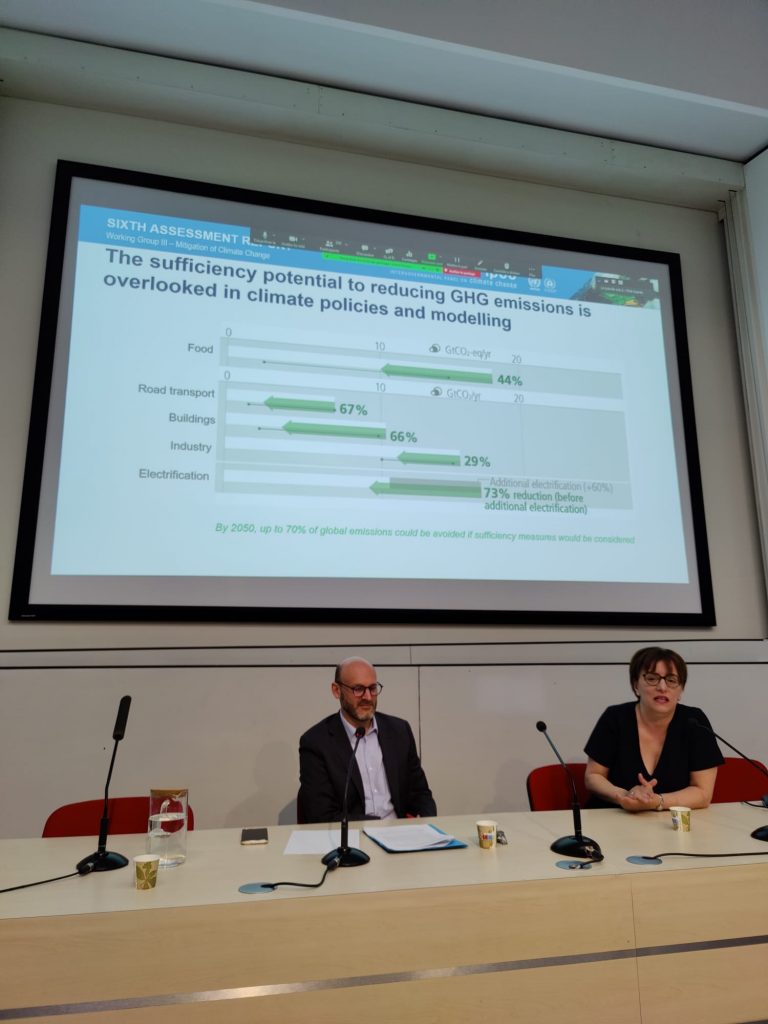

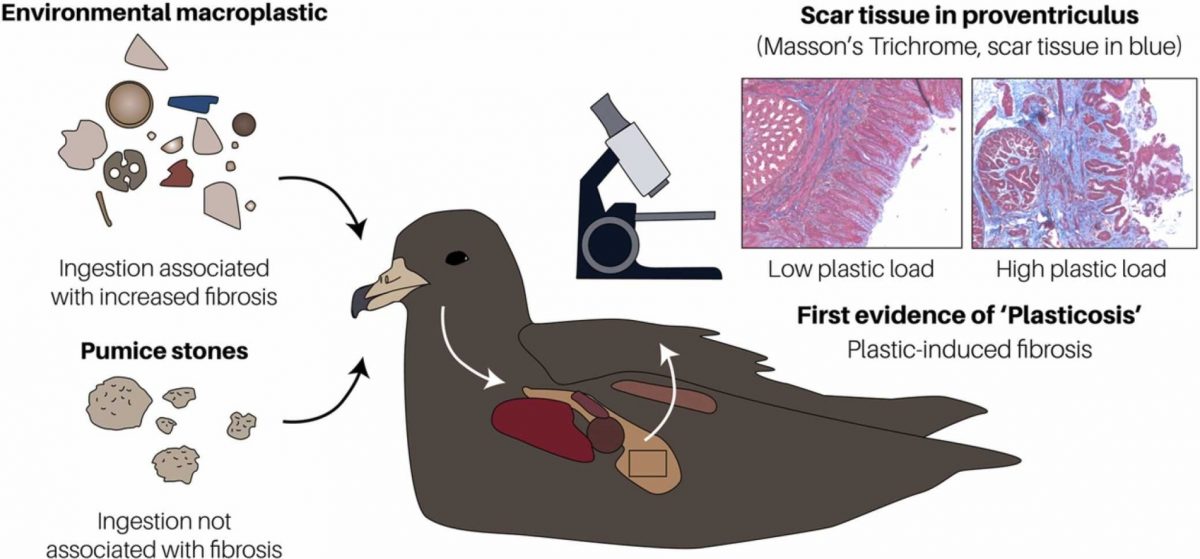

In order to find out whether different strategies take seriously the connection between overproduction and the enormous growth in the consumption of clothing and textiles, and the increase in the use of synthetic materials, we asked four questions to the strategies. First, we looked at whether the strategies discuss growth in production volumes and possible measures to stop this growth. Second, we examined whether they address the plastification of textiles. By plastification, we mean the increasing share of plastic fibres used for textile production. Third, we exmined whether they discuss the raw material for plastics, and fourth, plastic waste. The results show that none of these questions that can reduce the environmental impacts of clothing production are given a central role in the strategies. There were three types of strategies that were examined: policy, industry and NGOs’ sustainability strategies.

Important findings

The most interesting findings are related to the reduction of the use of synthetic fibres – the plastification. This is the question that receives the overall lowest scores: none of the strategies present clear, direct measures to halt plastification, though some of the public policymakers indirectly include such a goal, through goals of substituting fossil raw materials in the production with other materials, including bioplastics. Without stating how this tendency is to be reversed, the strategies raise concerns over the increasing volumes of fossil raw materials used in textile production. It is also suggested that synthetic fibres have important qualities that are needed and the strategy of substituting virgin plastics with recycled plastics is particularly present in the strategies of the industry stakeholders.

The Plastic Elephant is a part of the project Wasted Textiles, the goal of which is precisely to reduce the use of synthetic textiles and the amount that goes to waste. It is situated right at the core of the project’s goal and of course, the project is also the reason why our elephant is synthetic textiles (i.e., plastic). At the same time, we are building on work from three other ongoing projects at Consumption Research Norway (SIFO): CHANGE – about quantity, LASTING – about lifetime and REDUCE – about plastics in everyday life; and we thank our good colleagues from all the three projects for fruitful conversations as well as heated debates. We thank in particular Kirsi Laitala, Marie Hebrok, Harald Throne-Holst, Irene Maldini, Kate Fletcher and Kerli Kant Hvass for their thorough reading of the report and constructive comments.

The full report can be downloaded here.